Xi’an Dongxin Engineering Equipment Co., Ltd

Xi’an Dongxin Engineering Equipment Co., Ltd was established in 2011, We are committed to manufacture high quality Sandwich Panel Producing lines of diverse shapes. We have a great expertise in the production of polyurethane sandwich panel production line. We have developed innovative solutions that allow you to improve your production lines, and we offer to develop your ideas or requirements if necessary. We have experienced team that has worked for many years in the polyurethane industry, both in the automotive sector and in equipment manufacturing and construction. After a long and extensive use, our equipment has proved its high quality. Our line is designed for the continuous production of top-quality sandwich panels with different facings, panel thicknesses and the option of a core structure made of polyurethane or mineral wool. Our sandwich panel production line system is a fully automation equipment system to produce various shapes of sandwich panels using a rigid-polyurethane foam as a core material which is known as a top insulation in nowadays with low heat conductivity, heat reserving, high strength durability and availability at construction site. Our production line has stable performance, high practicability and good cost performance. Our solution is customized and our service is first-class. We are committed to providing optimal solutions to customers all over the world. Please contact us as soon as possible if you have any requirements.

Technology Strength

The biggest advantage is that customers can learn the actual operation process of sandwich panel production in the factory after purchasing the production line, so that customers can operate more smoothly after buying it back, save time and labor costs, get started quickly and greatly improve production efficiency.

Strict Quality Control system

Dongxin has quality control department which inspects each parts and component for no-standard products and adopts sampling inspection for the components of standard parts

Cost Saving

The production line has high quality, solid materials, stable performance and cost effective advantage, and it has won more repeat customers with high cost performance, forming a large number of customers' trust transmission.

Perfect Service

Provide professional customized solutions before sale, actively and patiently provide customers with the performance parameters of relevant equipment, and guide customers to purchase their own suitable equipment and solutions. After-sales service with professional Technical services

Why Choose Us

- Competitive Price

- Maintenance Offline

- Technical Support

Dongxin Services

Our service

Dongxin Provide Service and Support in Time

Spart Parts

Spare parts services are provided for all accessories used in the equipment provided by Our factory Stock. Parts with long lead times are in stock.

Upgrade

Dongxin will work with users to customize scientific and reasonable modification plans to make the equipment play a greater role.

Maintenance

Provide regular inspection services - arrange for experienced engineers to enter the factory to inspect equipment and provide maintenance services.

Emergency

When there is an emergency situation with the equipment, we can provide remote support and maintenance guidance to shorten maintenance time.

xi'an Working Office

Located in CBD of Xi'an

Add: No.68, Lougetai Village, Hancheng Street Office, Weiyang District, Xi ‘an ,China

Mob: +0086 18049481401 (same number with Whats App)

E-mail: sales@pu-sandwich-panel-production-line.com

Factory Address

Factory Address:Wangxiangtun Village, Guang’an Town, Dacheng County, Langfang City, Hebei Province

- Support In Time

- Multiple Oversea Project

- Professional Engineers

- Customized Design

Ask For Quotation

Request a Quote

Frequently Asked Questions

The advantage of Dongxin’ Sandwich panel production line can able to produce a sandwich panel with great quality,including flame-retardant and sound insulation and the heat preservation with very competitive price.

The production equipment has a highly integrated and linkage control system , Which centralizes all control points in the main control center , realizes the parameter linkage and fault self diagnosis of the whole line control ,and realizes the operation control , high level automation control system also saves manpower and reduces manpower loss for customers

Our products are designed with high power and lowerenergy consumption , the production line has fast reaction and low energy consumption , we adopt a new fully enclosed internal insulation design to control the energy consumption at a low level

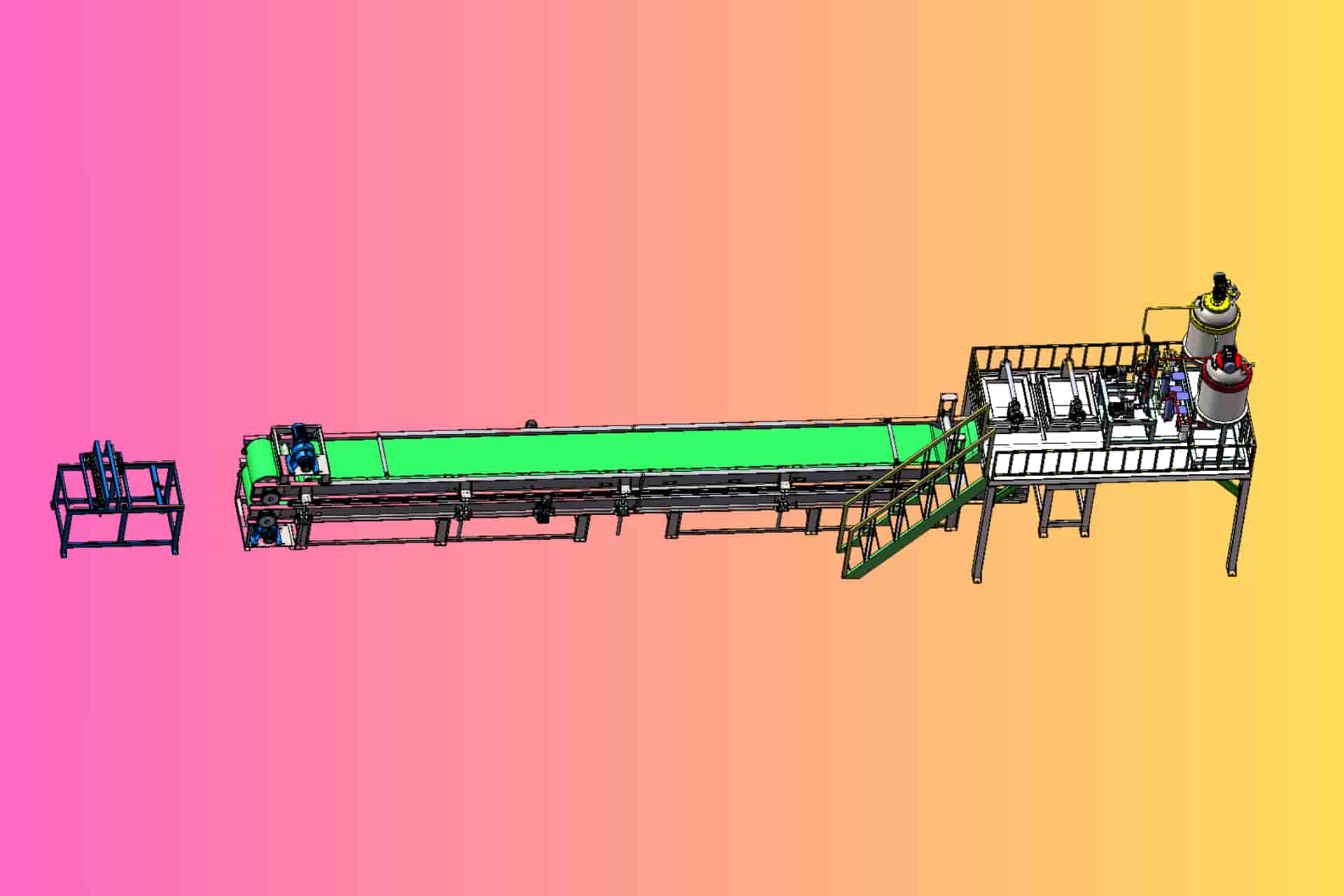

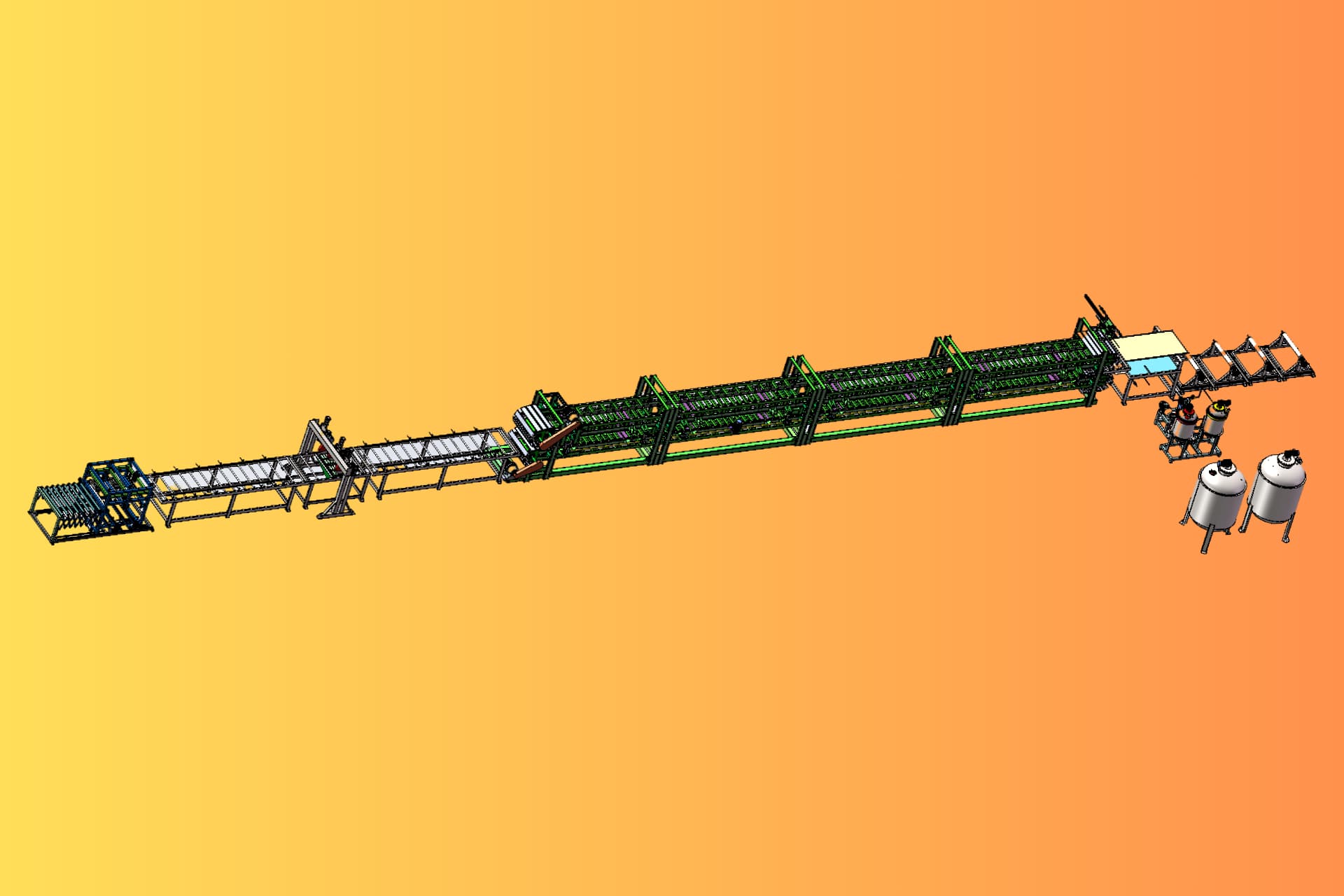

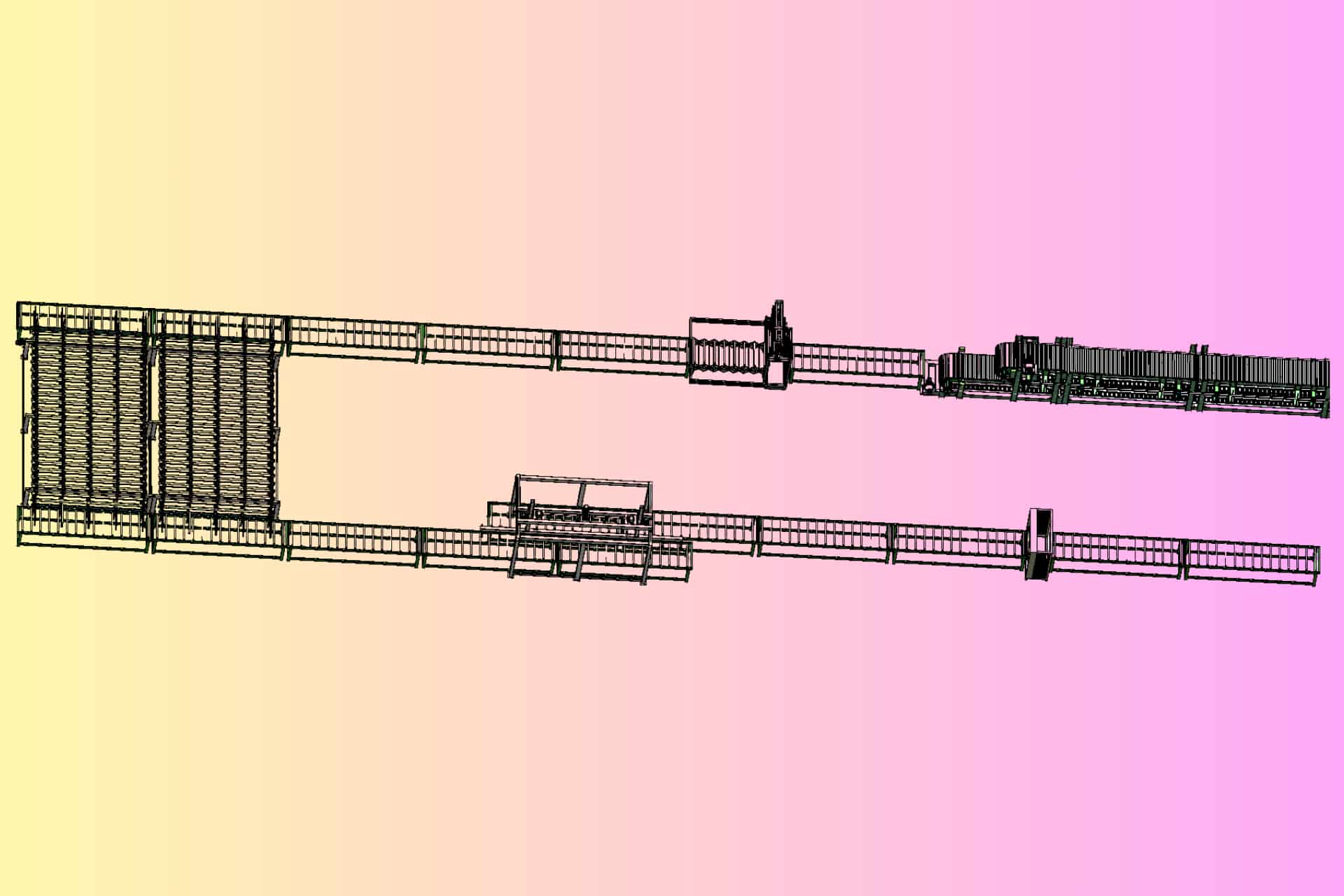

PU sandwich panel production line and Rock wook sandwich panel line consists of Decoiler , Film & Cutting system , Roll forming system , Heating System , Rock wool system ( Rock wool line ) High-Pressure Foaming system ( PU line ) , Double belt system , Band Saw cutting System , Coolling system ( PU line ) , Packing system .

Sandwich panel machine raw material includes : Pre-painted steel sheet , galvanized steel sheet , Aluminum sheet , Thickness 0.4-0.8mm, width maximum 1250mm

Pu/ Rock wool sandwich panel line : This sandwich panel machine can produce the sandwich panel which is a new type of building material , the products have the best function of heat preservation ,heat insulation, sound insulation, fire retardant ,waterproof,

our production line has high adaptability ,and is able to produce various kinds of sandwich board including PU, PIR and rock wook ,it can produce reliable products according to customer requirement with different designs and variety of configurations , it can quickly meet customer demand and the price system is also competitive and flexible

PU line/ Rock wool sandwich panel line 3-8m/min EPS sandwich panel line 1-6m/min

EPS sandwich panel line : 20-30 days , PU line/ Rock wool sandwich panel line :45-60 days ( According the different configurations ) the customer needs to prepare the foundation and tools in advance

Through different combination and configuration selection , and through simple switching , our production line can easily produce roof sandwich panel , wall sandwich panel , could storage sandwich panel and other products automatically , the inner core layer can be polyurethane , rock wool ,glass wool and other different varieties

Our Latest Shippment

Ship Out

Vietnam Customer

Ship Out

India Customer

Ship Out

Malaysia Customer

Ship out

Iran Customer